CHCESZ ZAMÓWIĆ U MNIE DOROBIENIE?

KLIKNIJ W LINK JAK ZAMÓWIĆ

Przeglądając stronę pewnie zauważyliście, że mam w zwyczaju dorabiać brakujące elementy. Tak już mam, że nie uznaję ułożenia puzzli do końca, jeżeli brakuje nawet jednego elementu :) Na szczęście nie rozpaczam tylko działam :)

Może nie będę zdradzać wszystkich “sekretów” bo każdy ma swoje patenty na dorabianie, tylko podam pokrótce jak to się u mnie odbywa.

Etap 1

Identyfikacja problemu i odseparowanie ubytku od pozostałej części.

Zazwyczaj wybieram 2 rzędy na około braku, jeżeli jest ich więcej to już stosunkowo tyle, żeby ewentualnie móc grafikę dorobić lub, żeby mi się ten owy “placek” nie rozleciał :)

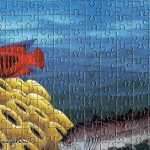

Takie kawałki skanuję min w 600dpi – ważne jest to potem do druku grafiki, fakt faktem do samego wydruku wystarczyłoby 300dpi, ale ja lubię mieć więcej szczegółów na monitorze :)

Etap 2

Uzyskanie odpowiedniego kształtu.

Tutaj niezbędny jest program do grafiki wektorowej, gdzie bawię się w rysowanie kształtu :)

Etap 3

Wycinanie.

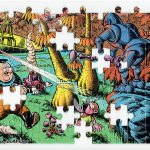

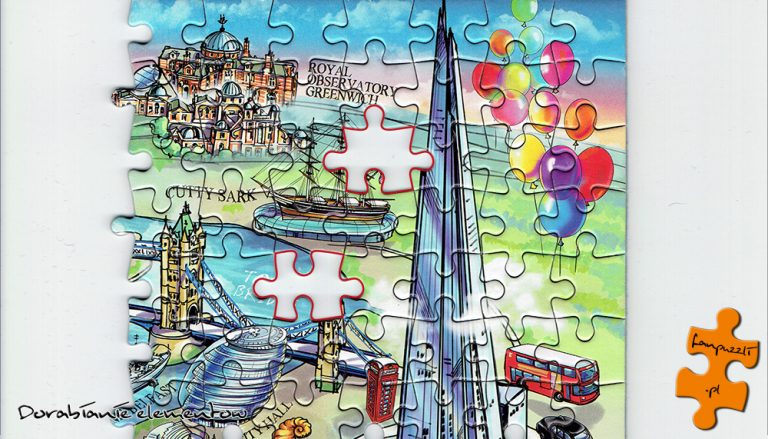

Teraz dzieje się magia wycinania (jak na magię przystało, musi być ona tajemnicza :)). Wycinam w tekturze litej około 3mm. Zdjęcie poniżej przedstawia akurat moje rekordowe dorobienia – uff :)

Po lekkim oczyszczeniu i sprawdzeniu czy elementy pasują w swoje miejsca, grzecznie czekają na grafikę.

Etap 4

Grafika – prawie ostatni etap działania i chyba najbardziej wymagający.

Zależnie od tego co mam do dorobienia mam kilka ścieżek postępowania:

1. Jednolite tło – idąc na żywioł po prostu ręcznie wypełniam ubytek kolorem z otoczenia (oczywiście w programie graficznym)

2. Wszystko pozostałe – tutaj najpierw szukam w internecie zdjęcia w dobrej rozdzielczości i z tego korzystam, jeżeli jednak nie znajduję to albo skanuję pudełko, albo robię zdjęcie pudełka w interesującym mnie miejscu. Następnie muszę spasować nową grafikę ze starą i miejscem i kolorystyką.

Kolorystyka jest tutaj bardzo zdradliwa, jak wiadomo to co widać na monitorze nie oddaje nam tego co “wypluje” nam drukarka. Ma na to wpływ wiele czynników, którymi nie będę was zanudzać :) Koniec końców robię kilka kopii jednego elementu i nadaję mu różne wartości.

Etap 5

Druk i wycinanie.

Najprościej jest drukować na papierze samoprzylepnym, nie trzeba się potem babrać z klejem :) Ja wybieram błyszczący ze względu na to, że puzzle po prostu są zazwyczaj w połysku czy to większym czy mniejszym. Niestety nigdy nie dopasuję się do tekstury oryginalnych elementów (znowu kilka czynników, którymi nie będę was zanudzać). Jest to jednak do tej pory znany mi najlepszy sposób na uratowanie kompletności puzzli.

No to mamy wydrukowane, trzeba jeszcze wyciąć znowu do kształtu puzzla (teraz się dzieje inna magia, ale dalej magia :))

Etap 6

“TADA”

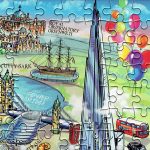

Następuje moment spotkania się druku z puzzlem :) czyli naklejanie grafiki na nasz dorobiony kształt i kulminacyjne zakończenie układania puzzli… czyli TADA :D

Z efektami jest różnie, czasem wyjdzie lepiej czasem gorzej, ale dziura załatana :) i z daleka na pewno ciężko na pierwszy rzut oka wypatrzeć, że coś było dorobione :)

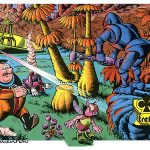

Na koniec mój pierwszy dorabiany element (nie wiem ile już dorobiłam od tamtego momentu, ale będzie ich sporo :))

Lista niektórych dorobień